Development of the demolition grapple and sorting grapple

|

Wednesday, June 8, 2011

In response to demands from the market, in 2010 D-TEC decided to start developing a demolition and sorting grapple.

Market requirement

There was a need for a robust grapple with features including a higher closing force and low deadweight, but still with a larger operating capacity. Besides these market wishes, the CE machines Directive and the Risk Analysis were compulsory preconditions for the development of this grapple range.

Development

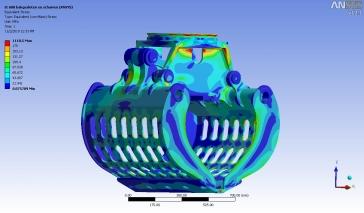

The experience that the D-TEC engineers have gained with high tensile strength steel (Domex and Hardox) meant that a prototype could be produced in a short space of time. The 3D development with the simulated finite elements method contributed to shortening the development time. Using FEM also makes it possible to decrease the construction weight.

Exhaustive testing

After internal practical testing the grapples were deployed in the recycling sector. And we were not afraid to use force. The grapple was coupled to a machine that was a class higher than is intended for the grapple. These practical tests revealed only minor improvement points, which meant that the grapples could be authorised for serial production.

Complete grapple line

The reception of this demolition and sorting grapple in the market was extremely favourable. A market demand has been met. The current grapple line supplies sorting and demolition grapple for machine class from 750kg – 1000kg to and including machines of 50 tons.

This is all with product features including:

• Extremely strong and rigid basic frame

• Cylinders with end damping

• Hardened pins

• Simple conversion to other widths

D-TEC: Lift up your profit!

|

|

|

|

|